Set R&D、 produce、 Sales、 Internal and external grinding、 Vacuum heat treatment、As an integrated modern technology enterprise

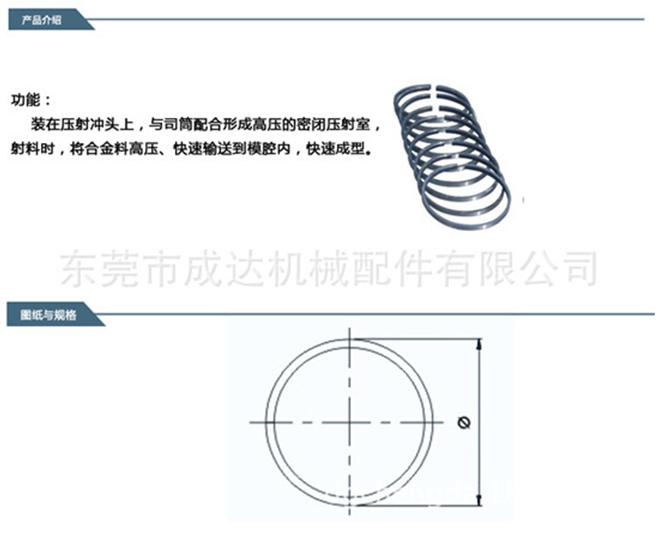

1. When installing the steel order, use the assembly and disassembly steel order tongs to spread the order. First install the order in the upper and lower grooves from the upper and lower ends of the hammer. The order in the middle groove can be lifted. The installed steel order in the groove and the lower groove is moved to the middle groove, and then the empty groove after the removal is reinstalled with a steel order to complete the installation; after the steel order is placed in the hammer head steel order groove, the steel order should be rotated flexibly, and The three openings should be staggered.

Requirements for use:1. The temperature of the zinc alloy solution in the crucible is controlled at 410~430 ℃. Too high temperature will increase the corrosion and wear of the steel wire;

2. The composition of die-cast zinc alloy must meet the requirements of GB/T13818-92.

Maintenance rules:1. Control the temperature of the zinc alloy material in the crucible vortex to 410-430℃. If the material temperature is too high, it will accelerate the corrosion of the steel wire, and the injection punch will be blocked in severe cases. (When the material temperature is normal, the zinc alloy liquid is grayish white, when the material temperature is too high, it is dark red);

2. Clean up the alloy slag on the liquid surface of the zinc alloy in the crucible in time. Once the alloy slag enters the barrel of the material pot, it will strain the steel wire, the injection punch and the barrel of the material pot, and the injection punch will be blocked in severe cases. ; Add zinc alloy material in time to keep the zinc alloy liquid level not less than one inch below the crucible to prevent the alloy liquid level from being too low, causing alloy slag to enter the cylinder;

3. The zinc alloy material should be kept clean and free of moisture, oil and other impurities;

4. The shutdown time is too long. Before the shutdown, the injection punch should be disassembled and the alloy liquid should be scooped out to 1/3 of the crucible, and the bottom of the hot probe of the injection furnace should not leave the alloy liquid;

5. Change the steel order regularly (recommended once a month and a half).