Set R&D、 produce、 Sales、 Internal and external grinding、 Vacuum heat treatment、As an integrated modern technology enterprise

Dongguan Chengda Machinery Parts Co., Ltd. (Wangda Die-casting Machine Parts Factory) is located in Dongguan City, an industrially developed Pearl River Delta region. For many years, our company has integrated R&D, production, sales, internal and external circular grinding, vacuum heat treatment, Vacuum nitriding and maintenance are integrated modern technology enterprises. Our company has a group of technical teams and sales teams with more than 10 years of experience in die casting machine parts processing, as well as high-precision production equipment, including CNC lathes, automatic lathes, milling machines, grinding machines (internal and external cylindrical grinding), and vertical grinding , Wire cutting, boring machine, gantry milling machine, vacuum heat treatment furnace, vacuum nitriding furnace, quenching furnace, etc. The production capacity is greatly improved, and the various production tasks proposed by customers can be completed efficiently and quickly. The product quality is more guaranteed and the delivery time is more punctual.

Processing, production and sales: Die-casting machine parts, Lijin, Yizumi, Fulai, Buhler, Hishinuma, Kazuka, Xingxing, Chenfeng, Weitai, Yousheng, Xinhong, Mingcheng, Zhengao, Noda, Ube , Toshiba, Toyo, Baoyang, etc. 15T-650T hot chamber zinc and magnesium alloy die-casting machine: material pot, nozzle body, nozzle head, piston ring, hammer head, heating sleeve, heating cake, temperature control rod and other accessories; 125T-4500T cold chamber aluminum, magnesium alloy : Barrel, plunger head, injection rod, connector, plunger oil, crucible, release agent, spray gun, pellet oil, melting furnace, pellet machine, manipulator, mold accessories: firing pin, firing pin sleeve, etc.; die-casting Machine maintenance, material pot replacement, etc.; the company has a complete and scientific quality management system. Integrity, strength and product quality have been recognized by the industry. Friends from all walks of life are welcome to visit, guide and negotiate business.

By virtue of its professional level and mature technology in the field of die-casting machine accessories, as well as its diversified information advantages in the Pearl River Delta, Chengda has absorbed advanced foreign processing, heat treatment, and nitriding technologies, and has undergone many years of technical practice, research and development and innovation. , The service life of parts is equal to the service life of imported parts. The die-casting machine parts produced by our company are sold all over the country and abroad.

1. Use Fushun electroslag remelting H13 or SKD61 material.

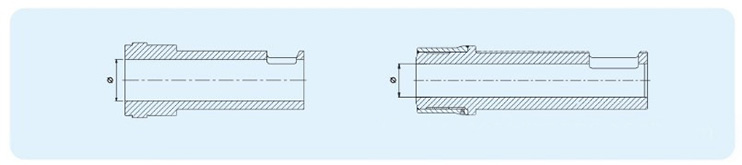

2. The inner hole grinding adopts deep hole internal cylindrical grinding, and the inner hole grinding does not connect the knife. It can be completed at one time, and the finish can reach more than 0.8; the external cylindrical grinding adopts through-mandrel grinding, and the roundness of the inner hole is the same as that of the inner hole. Axial degree, perpendicularity, etc. work 100% to meet the requirements of the drawings.

3. Heat treatment adopts vacuum high temperature quenching (1030°C~1050°C), secondary high temperature tempering (HRC42°~46°); surface treatment adopts glow ion nitriding (nitriding layer 0.25~0.30mm) , HV≥900~950 (equivalent to HRC62°~65°), the bottom layer has high hardness, high surface hardness, and the inner hole is not easy to be strained; it has good heat resistance, thermal fatigue resistance, and liquid metal erosion resistance.

4. The largest injection chambers we process are:

Ø101.6*167* within Ø40.

Ø260*1080*within Ø160

Ø340*1100* within Ø150.

Ø300*1275* Ø150 within.

The maximum service life of the injection chamber has reached more than 100,000 mold times. The product has the characteristics of stable performance, wear resistance, less deformation, and long service life.

5. The production cycle is 5-7 working days.

6. All businesses are welcome to submit pictures and samples to order; sincerely welcome everyone to visit the company to guide and learn from each other, thank you! !

|

Inlet barrel (injection chamber, melting cup, barrel) |

||||||

|

Basic parameters |

||||||

|

Die casting machine brand |

Specifications |

Processing equipment |

Heat treatment process |

Surface hardness (HRC) |

Material |

Warranty |

|

Li Jin |

160T-3000T |

Precision CNC machining |

Vacuum quenching, nitriding |

62-65 |

Fushun electroslag remelting H13 or SKD61 material |

One year or one hundred thousand mold times |

|

Yizumi |

180T-3200T |

|||||

|

Toyo/Toshiba/Ube |

150T-3600T |

|||||

|

other |

125T-3600T |

|||||